COMMERCIAL STRUCTURAL FABRICATION

Extension Steel for Putney High Street Refurbishment

Project type:Commercial / Residential

Location:Putney High Street

Services: Structural Fabrication, Crane Hire, Welding, CNC Steel profiling, Drilling, Cutting, Steel Erection

Project scope

Putney High Street is undergoing refurbishment and this project requires structural steel for a challenging extension. MAH Steel fabricators have got it covered! We supply structural steel fabrication to any part of London, and West London in particular.

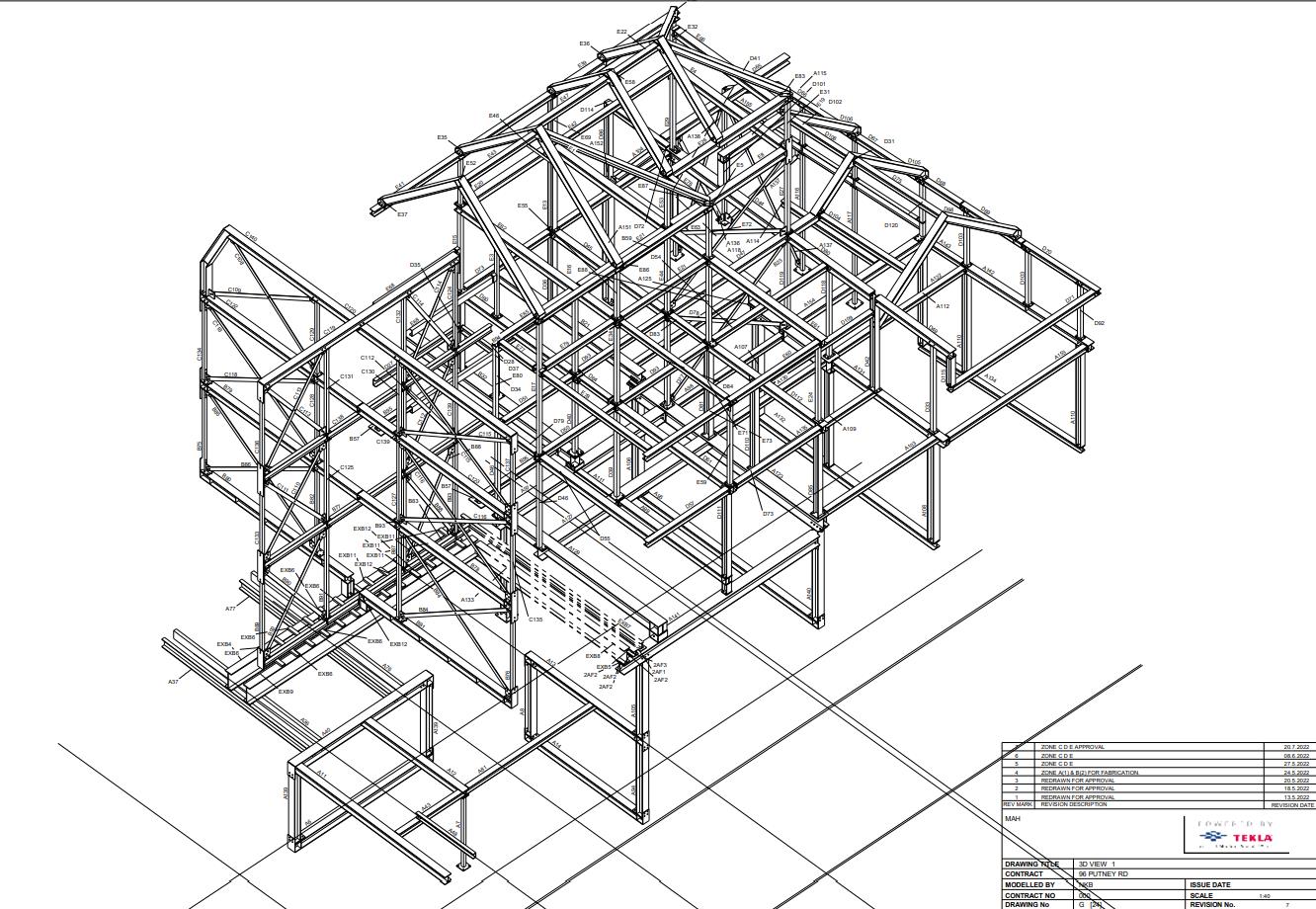

Firstly, we need to confirm what the project requires. The MAH Steel design team get to work on creating 3D drawings of the fabrication vision. As well as working to the highest quality, they’re also fast! Their designs are sent to the client for approval. Following a few amendments and tweaks, we reach a fully detailed 3d model general arrangement drawing, shown here. Now we’ve got the drawings, we’re ready for the fabrication to begin.

Straight to the saw

After checking and transporting all the steel to the saw, our skilled cutting and saw operators check the cutting list to confirm requirements. Using our CNC production line with millimetre tolerance, cutting the steel is always highly accurate. Combined with cleaning up and squaring off the ends, we ensure the correct lengths every time.

Once all the steel for the extension is cut, the team transport it by fork lift to the workshop’s fabrication area. Following a check of all steel by our in-house inspector to ensure it meets all CE requirements, it’s over to the fabrication team. After reviewing job tickets and the Tekla drawings by the workshop manager, the fabrication team are ready to get started.

Next step with the fabrication complete is quality control. We check all the hole drilling is complete and that the steel beams with end plates line up. When it’s given the thumbs up, it’s on to the final stage – finishing.

Extension steel finishes & delivery

To complete the the steel and make it ready for the extension project, it needs to have finishes applied. In this instance, it’s time for painting. We transfer all the steel to our MAH Steel paint booth and paint each piece efficiently and accurately. Once the thickness and quality check is complete, it’s outside to dry.

Finally, our loading team check each and every element to the steel order, making sure it’s all correct and present. Once approval is given, it’s safely and securely loaded on to our crane lorry by the loading team. Our skilled and safe driver delivers the order directly to the project site, unloading it exactly where it’s needed.

MAH Steel’s onsite installation team get to work erecting each piece of steel, tightening and fixing all bolts in place. Even our driver helps out too! With the challenging erection complete, the steel is checked by our team and the customer.

Only once we have a happy customer and their approval, is it a job we can sign off!

Our clients verdict

“ We always used MAH Steel for all our projects that require steel work. The latest project was supply & install, was avery challenging project, new extension to existing building and refurbishment internally . Internal works was most challenging part for steel installation team which went smoothly from start to finish, 56T of structural steel erected in less than 5 weeks with their 30m crane. Nothing was too much complicated even the crane driver was mucking in with the install! I would never go anywhere else for my steel. ”

Looking for trusted steel fabricators?

Let’s get in touch! Drop us a line or call 01322 276948.

Related services

Onsite Fabrication

Skilled onsite fabrication for all London based structural projects

Connection Design

We can fulfil all bespoke steel connection design for our Putney and South East clients