COMMERCIAL STRUCTURAL FABRICATION

Steel for a Baptist Church

Project type:Baptist Church

Location:

Services: Structural Fabrication, Cutting, Welding, Drilling, CNC Steel Profiling, Crane Hire, Zinc Primer, Steel Connection Design, Steel Installation, Steel Supplying, 3D Modelling

Project scope

It’s not every day you get to work on a steel project for a church.

The process started with the site survey being carried out by our experience team. Back from site the drafting, team can made a start on the drawings and issue them for approval.

The process

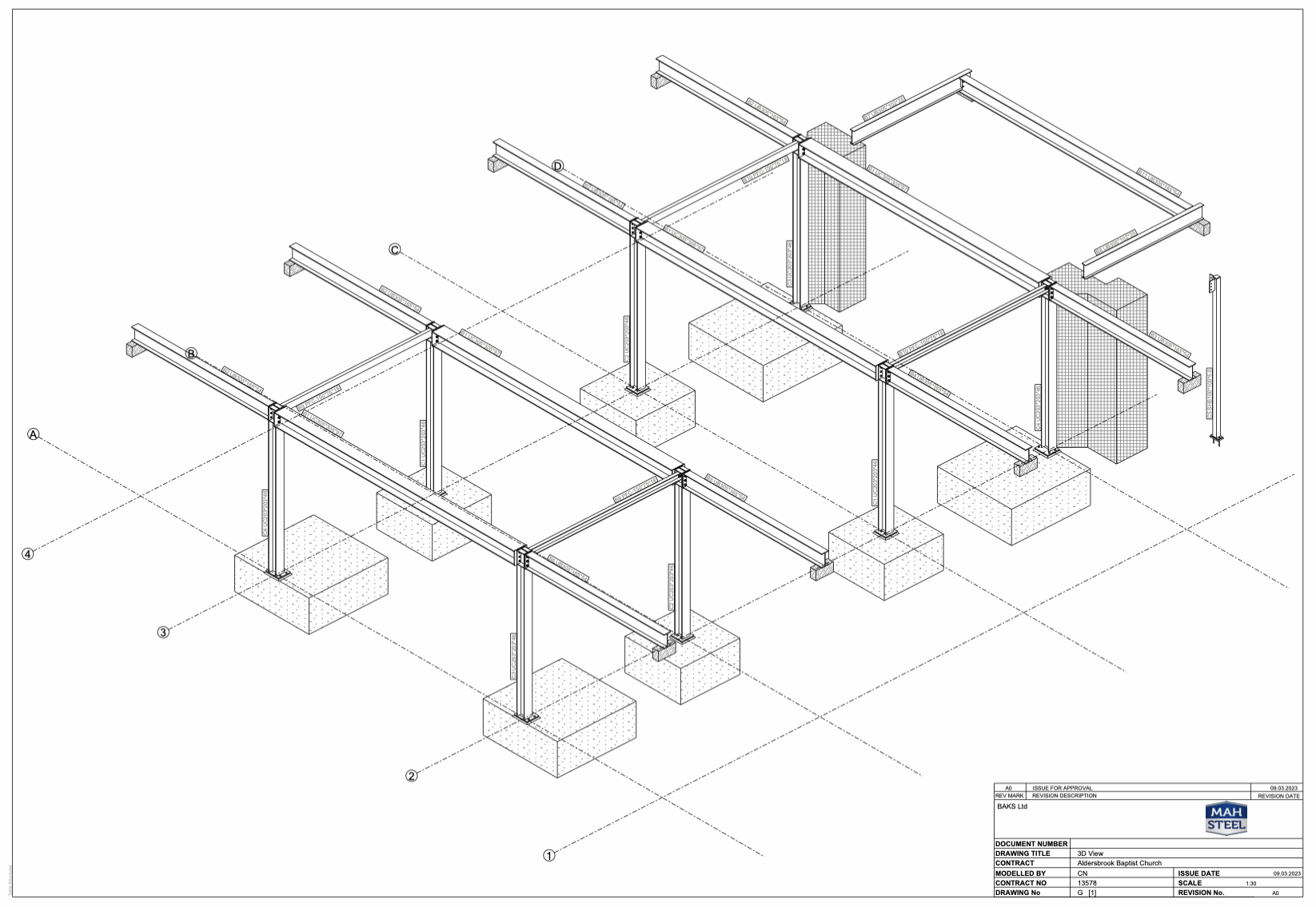

The process starts with the design team drafting drawings and modelling the structure on our 3d Tekla programme. Once detailed, this was then sent off to the client for approval.

Once approved, we then start on the all-important fabrication. The steel is fully processed, cut, drilled and fabricated as per the fabrication drawings into the various components. Depending on the application, the steel fabrication process may also include additional treatments such as shot blasting and priming.

Structural steel fabrication then was checked by our in-house QA team and then passed through to be fully welded to specification. With all components cut to spec and meeting specifications that the engineer has calculated, the steel can then be fabricated and welded. All steel welding is checked for accuracy and quality. Our steel welders are highly qualified and professional, such as the whole team! They hold all the necessary qualifications to complete every job to the highest standard.

After that, we’re moving to the next stage: steel finishes, and then the delivery and installation.

The Result

The steel is then sandblasted and primed in our newly built spray booth.

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. A pressurised fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material. All steel finishes also provide aesthetic style and environmental protection.

The final step – the delivery is on time and the steel is correctly offloaded and stored on site ready for the installation. Off to the next one!

Our clients verdict

“ First job that I done with Ben and the MAH Steel team and from start to finish it went smoothly and the steel fitted perfect.

This is somewhat a tricky project, but Peter and Chris attended site to carry out the survey and from the moment they arrived I could tell they knew what they were doing, they understood the job and worked alongside the site manager to take the dimension required to manufacture the steel.

Overall, it was great experience with good communication throughout, will defiantly be using the MAH team again. ”

Looking for steel for a bespoke steel fabrication project?

Don't hesitate to get in touch. Let's discuss it together.

Related services

CNC Steel Profiling

Complete CNC steel profiling, carried out to the finest millimetre.

Steel Finishes

The final step in the steel manufacturing process, steel finishes provide aesthetic style and environmental protection.

3D Modelling

We provide 3D structural steel modelling for loft conversions and conservatories through to large commercial buildings.