COMMERCIAL STRUCTURAL FABRICATION

Extension Project in Bromley

Project type:Residential

Location:Bromley Area

Services:Structural Fabrication, Cutting, Drilling, Fire Paint, Delivery Crane Hire, Steel Supplying

Project scope

The customer contacted MAH Steel, needing fabricated steel for house extension project in Bromley.

Smaller scale steel projects, such as a house extension, require just as much care and attention as larger scale ones.

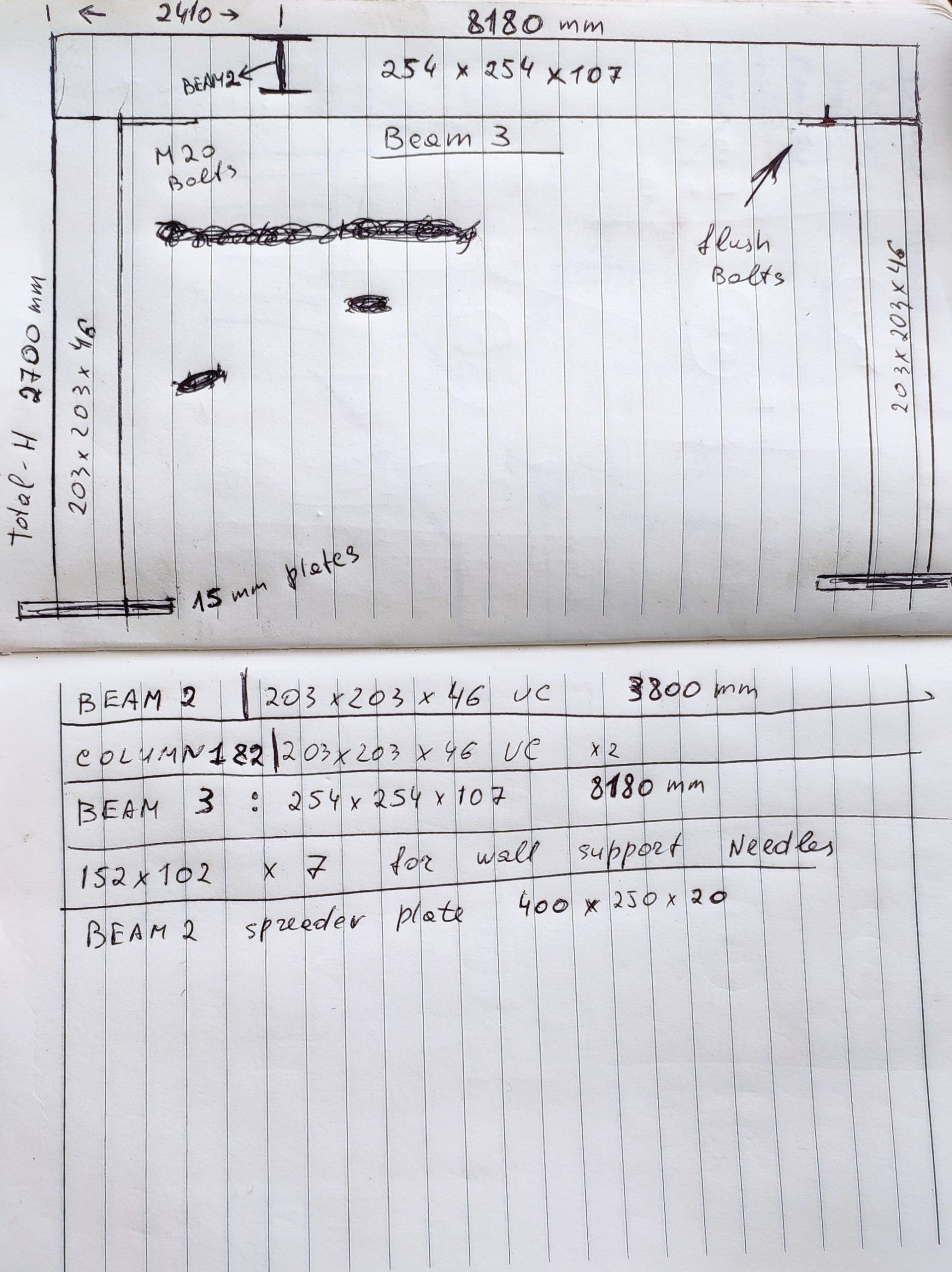

For this job, we received drawings from our customer. You can see it on the right hand side. So, we turned it into a drawing that our customer could sign off!

Once the plan has been approved, steel fabrication CAD drawings were produced. With all preliminary checks complete, it’s time for transportation to the saw!

The Challenge

We don’t just provide steel fabrication services, we offer a complete package from initial concept to final steel installation. So, once the drawings have been issued, steel gets to our yard by our trusted steel supplier. Then it gets offloaded by our loading team.

It was very handy to take part in this fabricated steel project in Bromley as our steel fabrication workshop is located literally next door in Gravesend, Kent! Besides, we’re a proud sponsor of Bromley FC, so we work in Bromley quite often.

So, once it’s all offloaded, our cutting and saw operators check the cutting list and cut steels to the required measurements. To ensure the correct cut lengths are achievable the end must be cleaned up and squared off.

Once we cut the material, then we transport it by a forklift to the steel fabrication area, ready for our experienced steel fab team to start the project. Our workshop manager issues job tickets and Tekla drawings. Before the steel fabrication team start, our in-house inspector checks all material once again! It’s very important to pay such attention to details every step of the way. Quality control is the key!

Once the project has been manufactured, it is then checked again to make sure the right holes are drilled and the beams with end plates line up.

The Process

After that, the steel is taken to our paint shop to be painted. Another important thing about steel finishes, is to use the correct thickness of paint in microns. It also requires unbelievable precision. Then we hang our freshly painted steel in the yard to dry.

Once again, it’s checked by the loading team that all steel is correct to the delivery notes. After that, it is loaded onto one of our crane lorries and delivered to site to exactly where the customer wants it. On this occasion, this was over a fence into the back garden.

The customer was then asked to check that they are happy, and everything is correct. The job was then signed off. Off to the next one!

Our clients verdict

“ Hope you are well and thanks for recent delivery. Pleasure to do business with you guys, always there to assist, brilliant workmanship and delivery on time as promised every time. ”

Looking for steel fabricators in the Kent area?

Look no further. At MAH Steel we have a massive number of solutions for your bespoke steel project. Drop us a line, and see how we can help.

Related services

Steel Finishes

The final step in the steel manufacturing process, steel finishes provide aesthetic style and environmental protection.

Steel Erection

MAH Steel team follow your steel fabrication project from initial ideas directly to your site.